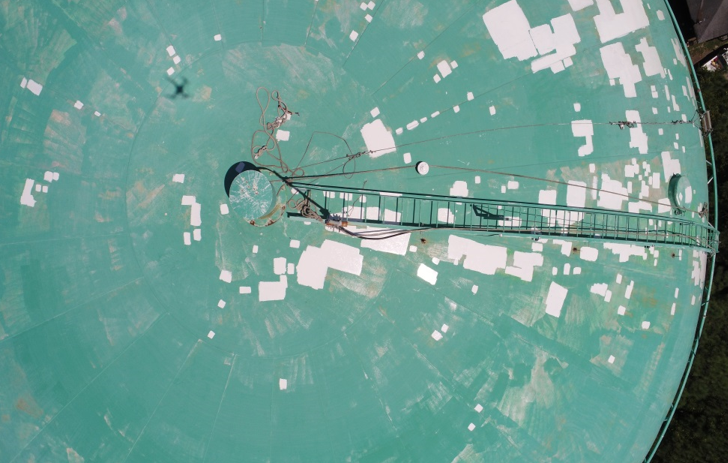

We are partnered with QCC Services LLC to provide high quality corrosion/coating condition assessments, construction inspection, coating construction inspection, and drone services. Chief Pilot Ryan Cox is a certified private pilot and certified part 107 sUAS Pilot with years of experience performing inspecting services. QCC Services LLC Has qualified NACE CIP Level 3 staff and also teaches the CIP level 1 & 2 courses with over 20 years of construction inspection and 15 years of NASSCO certified SSES and I&I studies experience.

“Protecting Tomorrow, Today”

Technical 3rd Party Inspection

“What Could Possibly Go Wrong watching paint dry”

What is NACE?

National Association Of Corrosion Engineers

Why is NACE Important?

Industry Leading Technical Education For Coating and Corrosion Expertise

What can NACE do for your Concrete and Steel Assets?

Extend Coating Lifecycles With Advanced Assessment and Inspection Knowledge

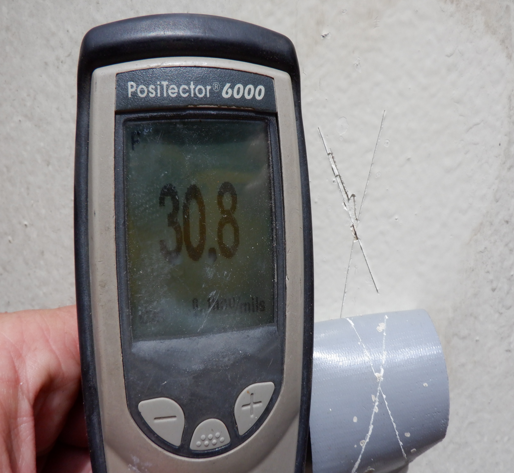

ASTM D 3359 Method A & B Measuring Adhesion by Tape Test

ASTM D 3359, Standard Test Method for Measuring Adhesion by Tape Test, describes two methods to measure adhesion by the tape test. Equipment Description Method A The only equipment required for Method A is a sharp knife and the special tape required to cause the pull-off. Method B Use a cross hatch cutter or a razor-sharp knife to score through the coating down to the substrate.

Make a series of cuts at right angles to each other to form a grid of small squares. A range of cutting blades are available for different thicknesses and types of coating. Apply the tape as required by ASTM D3359 to the surface and remove. Visually assess adhesion by comparing the grid of squares against standards.

ASTM D 3359 Method A

Proper Use. Method A (Test Procedure) In Method A, an X cut is made in the coating film. This method is used for coating films thicker than 127 μm or 5 mils

ASTM D 3359 Method B

Method B (Test Procedure) Note: Test Method B is not considered suitable for films >5 mils (12 microns). Method B can be used above thickness greater than 5 mils (127 microns) if agreement between the purchaser and the seller is achieved and if wider cuts are used. If making the cuts individually: Make a series of cuts at right angles to each other. For films thinner than 50 μm (2 mils), make 11 cuts 1 mm apart in each direction. For coating films from 50 to 127 μm (2 to 5 mils) thick, make six cuts 2 mm apart at right angles to each other (Figure 19.9). If using the cross hatch cutting tool: Select the appropriate cutting blade, six or eleven, required for coating thickness. Press the blade to the surface, and pull the tool once in each direction to form a 90° angle grid